Cross Belt Sorter Conveyors

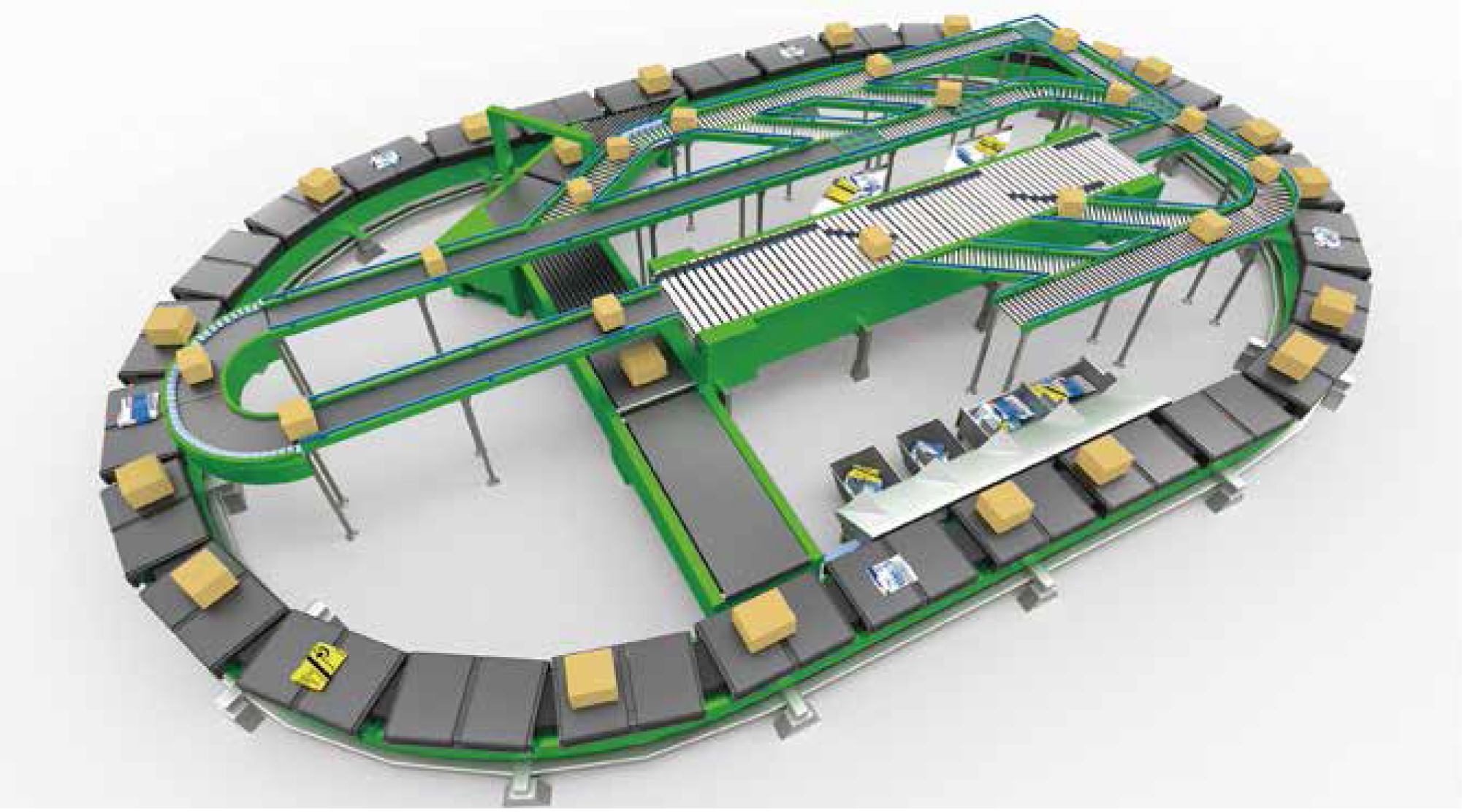

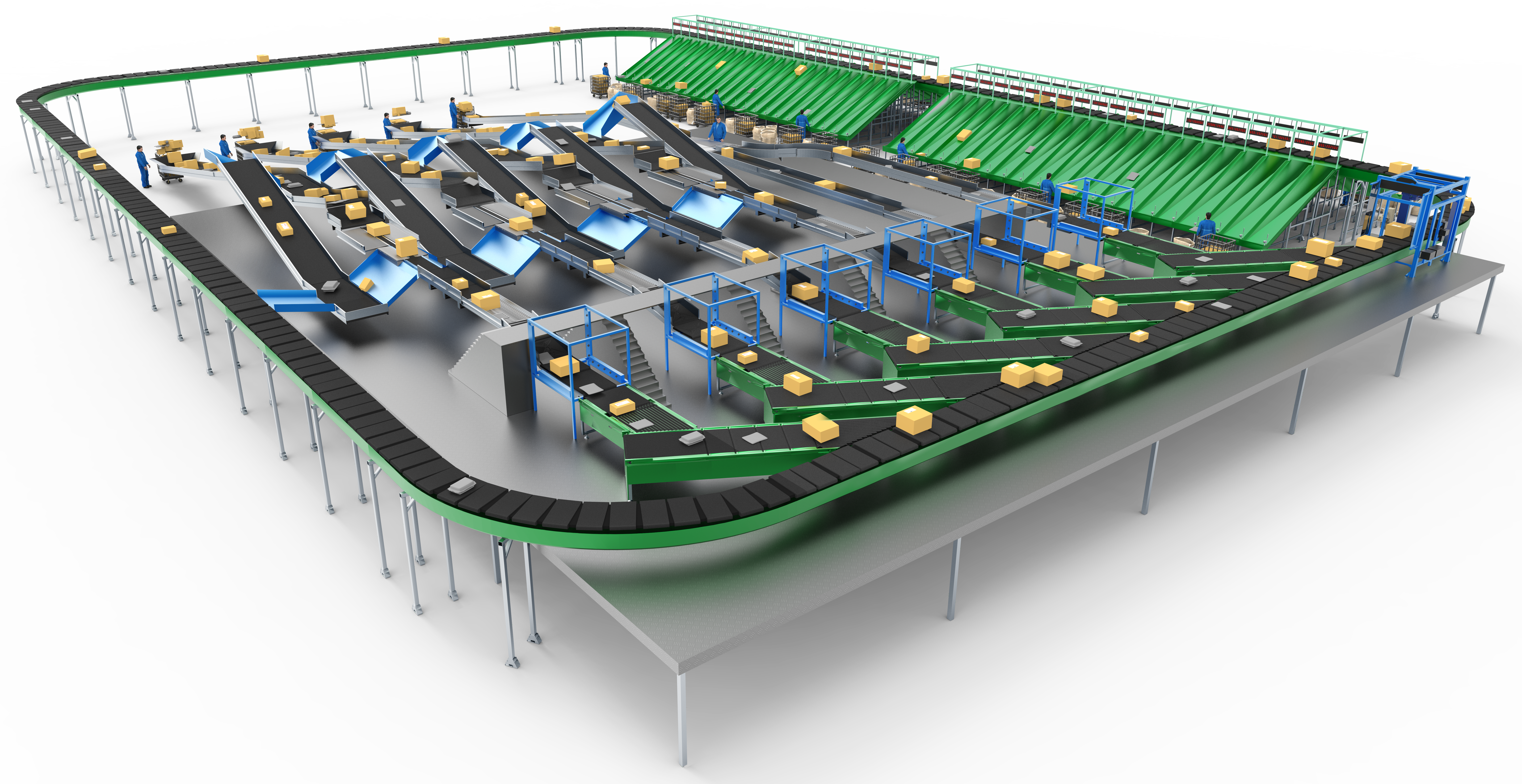

Cross Belt Sorters are fast and efficient logistics sorting systems, which consists of a main drive belt which pulls along trays. When a tray reaches its specific sorting destination, the bi-directional belt on the tray will engage and transfer the goods at 90° to the main direction of flow, either left or right into its sorting station.

In addition to high speed and sorting efficiency, it can also handle items of various specifications and sizes, including fragile items and items with a high friction coefficient. These conveyors can also do sorting to both sides at the same time.

Horizontal cross belt sorters are flexible and can use space optimally by using bends to fit into small spaces. The sorter can also run at an incline or decline. To save space two sorters can run on top of each other, allowing for simultaneous conveying. The in-feeds and out-feeds can be arranged anywhere along the horizontal cross belt sorter making it possible to create multiple sorting or discharge areas. Horizontal cross belt sorters can run goods recirculation for unrecognized goods or for when the discharge stations are full.

Benefits of the horizontal cross belt sorters

-

Low energy consumption linear motors, non-contact drive, high efficiency and energy saving

-

Sorting of items of various specifications and sizes.

-

Achieving efficient sorting of fragile and high friction coefficient items.

-

Real-time dynamic tracking technology, system monitoring, diagnosis and security protection functions.

-

Modular design, easy maintenance, high stability.

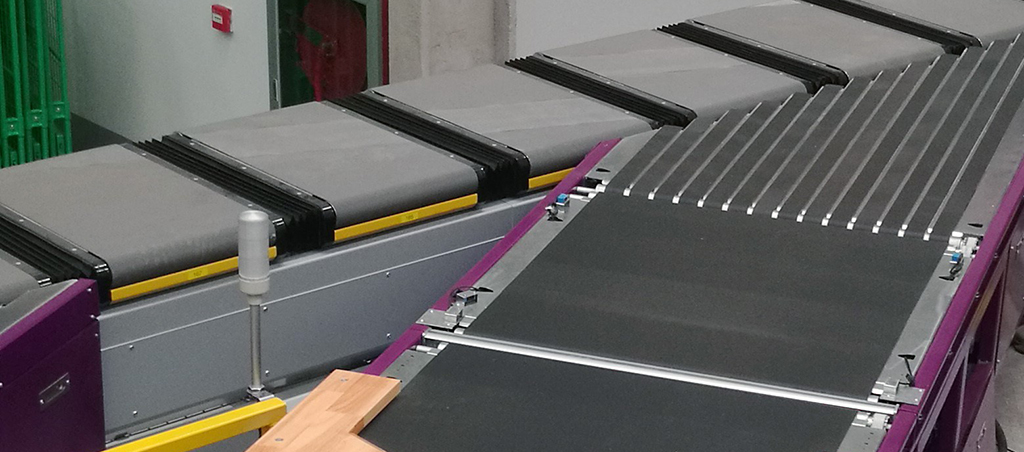

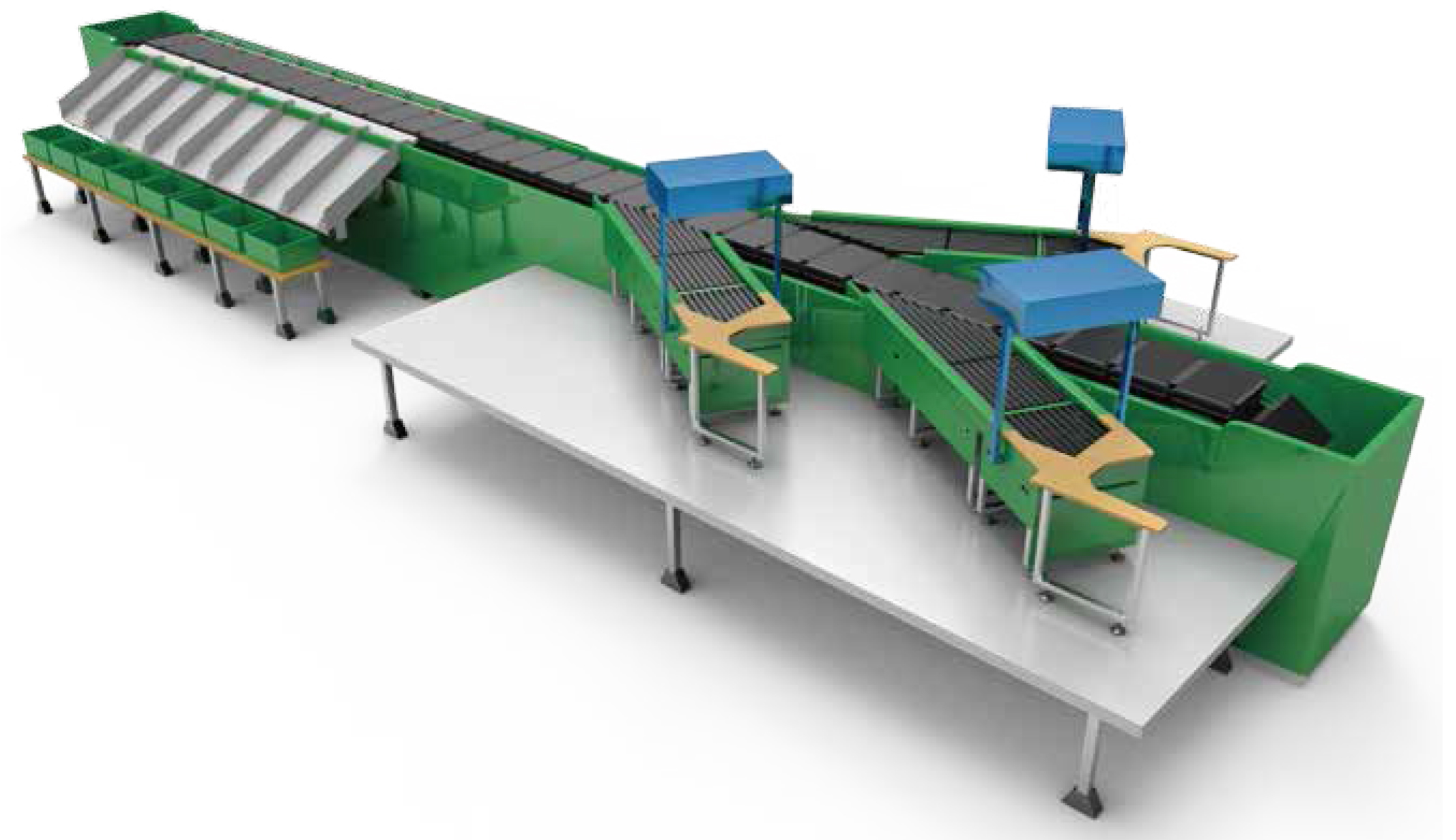

Linear / vertical cross belt sorters run in a straight route with the drive belt running on the top and returning on the bottom. This vertical circulation has a compact modular structure which allows for extreme space-saving. The standard modular design can be customized to the number of out-feed ports according to clients demand.

Benefits of the linear / vertical cross belt sorters

-

Modular structure, easy to assemble, easy to maintain.

-

Sorting is fast and accurate, no impact of goods. It has a prominent advantage in soft bag transportation.

-

Strong applicability. By adjusting the number of trays, it can realize the sorting of goods with larger lengths.

-

Items can be sorted to both sides.

-

Small foot print, more flexible space arrangement, free increase or decrease of exports, convenient for flexible application of customers.

Cross belt sorter conveyors are widely used in the express distribution centers because of its high sorting efficiency and capacity.

Technical Detail

Linear / vertical cross belt sorters

Pamphlet

Cases / Projects

-

STO Express Cross Belt Sorter

STO Express Cross Belt Sorter - VIPSHOP Cross Belt Sorter

- BEST Express Cross Belt Sorter

- ZTO Express Cross Belt Sorter

- YUNDA Cross Belt Sorting System (SHIJIAZHUANG)

- YUNDA Double Layer Cross Belt Sorter (YIWU)

- KUAYUE-Express Cross Belt Sorter

- YUNDA Double Layer Cross Belt Sorter (JINJIANG)

- GUANGZHOU TAIRE Cross Belt Sorter

- YANWEN Express Cross Belt Sorter

|

Follow us on: |

|||

|

|

|

||